Each message is a fixed length and contains different parameters such as RPM, coolant temp, vehicle speed, etc etc. Mode 1 is used for getting the operating parameters out of the ECM, in mode 1 there are also many different messages. The most commonly used modes are Mode 1, 2, 4, 8, 9 and 10 Mode 13 - Security Seed/Key on Flash PCMs Mode 11 - New mode or in VU/VX/VY part of the security system Mode 6 – Address Of Routine to Execute (GM Development)

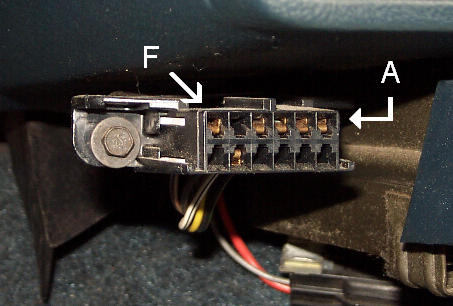

#Aldl connector download

Mode 5 – Enter Download Mode (GM Development) Mode 3 – Request 6 Particular Bytes of Memory Mode 1 – Data Frames (There are many different message frames) There are a number of different ALDL modes… The 8192baud ALDL is far more useful than the 160baud data for many more reasons than just being faster.

The ECM does not lock the timing to 10deg BTDC when requesting data so it is possible to drive the vehicle like normal while logging. No resistor is required to tell the ECM to start transmitting data. VR/VS/VT – Being a bi-directional data link it is now possible and necessary to request data from the ECM/PCM. It contains information on diagnosing faults and checking sensor outputs.

The data that is sent over 160baud ALDL is very basic and is a fixed data stream. The disadvantage is on a factory memcal it also locks the spark advance to 10deg BTDC until 2000RPM, this can be disabled by editing the memcal binary. This tells the ECM to start outputting data on the CEL wire. VN/VP – This is a uni-directional data link so to enable ALDL data a resistor must be placed from the diagnostic enable wire to ground. How It Works: Due to the different types of ALDL there are different ways to get data out of the ECM… The PCM is linked to the BCM, ALDL is used for the linking process. VX and VY – The NA V6 uses a flash based PCM, this also added some new ALDL modes for the security system. A regular message containing all the dash information is sent at the request of the BCM. The VT took the data bus further by also including the instrument cluster. It is also 8192 baud but the major difference is the bus master is no longer the PCM but instead the BCM. VT – This is a very similar implementation to the VR and VS ALDL. PCM Device ID - $F4 for VR V8, VR V6 and VS V8. This way only the device that is addressed process’s and responds to the packet, all the others ignore the data.

Every device on the bus has a device ID, so when data packets are put on the bus it is ‘addressed’ to a particular device. In VR and VS applications the bus master is the ECM/PCM. This data bus allows for only one device to communicate at a time and connects all the major modules – BCM, ABS, SRS, ECM etc. The purpose of the transceiver is to convert the transmit and receive lines of the processor UART into a single wire half-duplex data bus to allow the ECM to communicate on the vehicle bus.

It is a bi-directional half-duplex data link using a hardware UART in the processor and a Delco/Delphi transceiver IC. VR/VS – The second and probably the most widely used type is 8192 baud, this is also used in many GM built US vehicles from the mid/late 80s to the late 90s and often referred to as OBD-I. When ALDL is enabled the CEL will flash with the data. On every interrupt a bit is applied to the CEL wire, 6.25ms = 160Hz or 160baud. The 160 baud rate is due to the ECM operating with 6.25ms minor loop interrupts. It is ok for slow data speeds but puts too much load on the microprocessor for high baud rates.

#Aldl connector serial

Bit banging is a method to transmit serial data using only software rather than a hardware UART. The ECM uses a ‘bit-banging’ technique on the CEL (Check Engine Light) wire to flash data out bit by bit. It operates at 160 baud and is a uni-directional (read only) data link. VN/VP – This was the first implementation, was also the most basic and is the only implementation that uses ALDL for purely diagnostic purposes. There are a few different implementations of ALDL… It is used for a variety of things from, as the name suggests, initial system testing when the vehicle is manufactured to vehicle module communications to diagnostics at the dealer/home to real-time tuning. What It is and What Can It Do: ALDL stands for Assembly Line Diagnostic Link. About: This information will be updated from time to time and serves as a basic introduction to GM ALDL, specifically aimed at GM Holden Commodores.

0 kommentar(er)

0 kommentar(er)